For smaller catering, hotel and

commercial operations up to 35 people.

The fully biological SBR wastewater treatment plant for multi-chamber cesspits and multi-tank plants up to 35 people – for new construction and retrofitting.

Especially developed for highly loaded wastewater from hotels, catering and food processing operations in smaller sizes: the “G” variants of our AQUAmax® PROFESSIONAL. Extensive adjustments to the tank as well as installation and maintenance tasks underwater are a thing of the past; even the retrofitting of old wastewater treatment plants is possible without excavation. Due to the AQUAmax® modular system and software updates, the AQUAmax® PROFESSIONAL G is always expandable and can be adapted to the state of the art or new legislation, without having to invest in a new wastewater treatment plant. The most important thing: The AQUAmax® PROFESSIONAL G achieves a treatment efficiency of up to 99%, even under the most difficult conditions. Plus: Even the nitrogen removal in accordance with German Standard DIN EN 12566, Part 3 is not an issue. All components of the Aquamax Professional G are UL certified for usage in the North American Market.

Our standardised AQUAmax® PROFESSIONAL G plant series

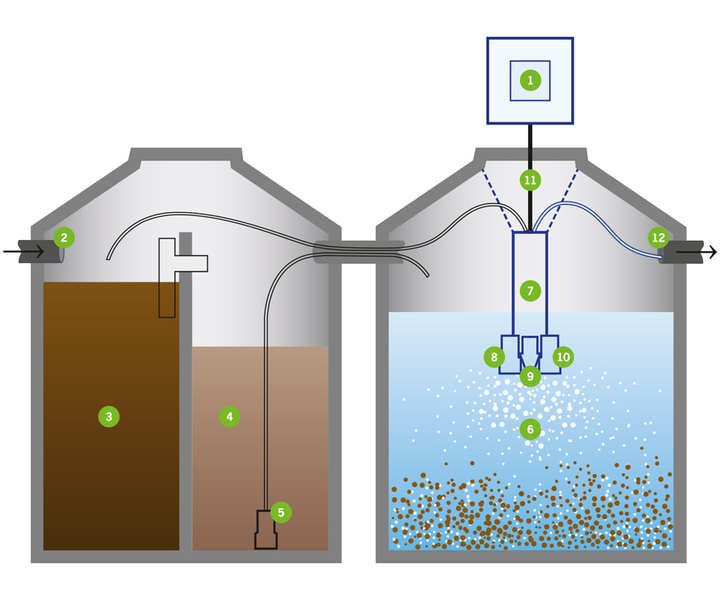

Functional Procedures

proControl© – the control centre for the AQUAmax® PROFESSIONAL G wastewater treatment plants

A text display with four lines, modern menu management and the possibility of software update through the integrated interface make this control unit not only the switching unit for the eight-hour treatment cycles but also into the true high-tech control centre for small wastewater treatment plants. Whether it is weekly running times, manual interventions or functional interruptions – each action is recorded in an electronic logbook, similar to the telephone book in a mobile telephone. Thus, for example, the maintenance service can still view all important events even after the elapse of several months. The voltage detection system UVS, in addition, ensures that a drop in the supply voltage does not remain unnoticed. With this, naturally the ATB has thought about the future. Should the statutory requirement increase further, with proControl© 2 you can profit from all further developments through the Update and Extension option – also still years ahead. Through this the treatment performance of the wastewater treatment plant can always be improved further. This is also possible today with the AQUAmax® PLUS packet (nitrogen degradation) and phosphate precipitation.